Installed Power (kW): 2x2x100+;2x25+11;2x 2x100+;2x25+11; 2x2x125+;2x 25+11;2x 2x160+;2x40+11; 2x2x150+;2x 40+11;2x2x200+;2x40+11; 2x2x200+;2x55+20;2x2x250+;2x90+20

Mining Height (m): 1.2~2.5;1.4~2.6;1.2~2. 6;1.3~2.8

Coal Seam Inclination Angle (°): ≤3.5;≤4

Coal Hardness (f): ≤35

Surface Height (mm): 816;870;856;870;900

Minimum Dinting Depth (mm): 207;306;400;486;302

Draught Speed (m/min): 0~7.5;0~6.3-10.3;0~8.7-14.5; 0~11.6-18.5;0~15.6-21.7

Draught Force (kN): 350;435/310;510/306;525/328;625/450

Draught Form: AC Variable Frequency Conversion Velocity, Gear/Pin Rack Driving

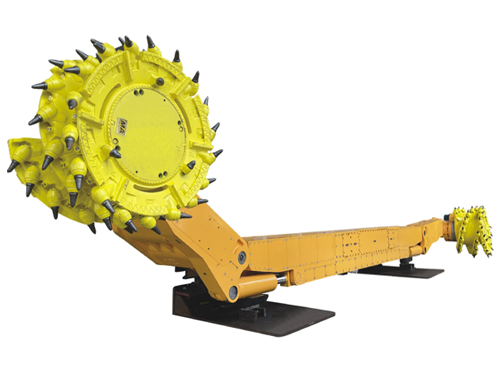

Drum Diameter (mm): Ф1100, Ф1250, Ф1400;Ф1250, Ф1400;Ф1250, Ф1450, Ф1600

Drum Speed (r/min): 63, 54;45, 51;59;52, 53;50

Effective Cutting Depth (mm): 630;630, 800;800

Supply Voltage (V): 1140;3300, 1140;3300

Operation Mode: Remote Control, Manual Control of Central and Both Ends Operation Stations

Dust Suppression Mode: Internal and External Spray

Design Production Capacity (t/h): 500;700;980

Maximum Non-detachable Dimension (mm): 2440x940x700;2693x1690x660;2455x1950x837; 2340x1490x720;2693x1540x720;2380x1358x720; 2338x1490x730;2380x1358x720;3130x1198x755

Maximum Non-detachable Weight (kg): 3500; 4361, 5720;5300;6200;9100

Total Weight (t): 24;26, 28;34;36;45/50

Match Feeding Machine Model: SGZ630;SGZ730, SGZ764;SGZ730, SGZ764, SGZ800;SGZ800, SGZ900, SGZ1000

Both cutting motor ishorizontally arranged, and AC variable frequency chainless electric traction method is adopted. Compared with models of the same power, it has the characteristics of higher power, lower machine surface height, and larger coal passing space. It has strong adaptability to coal seams and a strong ability to cut hard coal or dirt bands, pass through faults, and climb slopes.

The design adoptsan overall double curved ranging arm structure, with a large amount of undercover, large coal loading port, and good coal loading effect.

The upper part of themachine body is arranged in an inclined manner to adapt to the top beam of the hydraulic support, maximizing the reduction of the machine surface deviation. ensuring the requirement of low surface height.

With independentmechanical transmission systems and drawer-type installation, the electric control box is equipped with a flat windowless design and simple structure, which is easy to disassemble and maintain.

The entire machinehas good vibration resistance and a heavy body. A detachable counterweight plate is installed on the upper part; a dedicated anti-vibration device is installed inside the electrical control box.

Adopting airborneABB frequency converter, driven by "one tow one" traction mode, it is more adaptable to stability in the low-frequency range. The electrical system is equipped with a four-quadrant frequency converter to meet the requirements of high-angle coal mining faces.

The control systemadopts a DSP/ARM control system screen display.

IntelligenceThe machine has advanced control and protection functions, video monitoring, a self-diagnosis system, intelligent planning cutting, and automatic triangular coal cutting functions.

Remote communicationThe machine has multiple remote communication methods