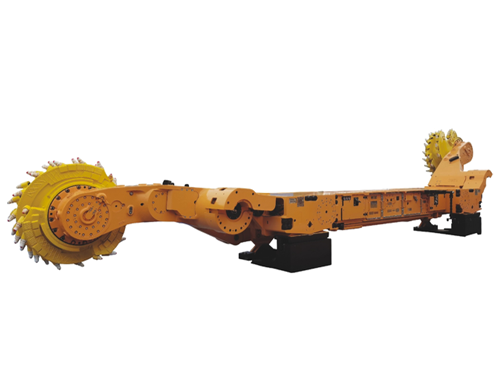

Installed Power (kW): 2400+2x55+20;2x450+2x75 +30; 2x500+2x75+30

Mining Height (m): 1.8~3.5;1.8~3.6

Coal Seam Inclination Angle (°): ≤35

Coal Hardness (f): ≤4

Surface Height (mm): 1260;1300;1260

Minimum Dinting Depth (mm): 425;406;425

Draught Speed (m/min): 0~8.0-13.3;0~10-17;0~10-17

Draught Force (kN): 725/430;766/458;766/458

Draught Form: AC Variable Frequency Conversion Velocity, Gear/Pin Rack Driving

Drum Diameter (mm): Ф1600, Ф1800, Ф2000

Drum Speed (r/min): 33, 37

Effective Cutting Depth (mm): 630, 800

Supply Voltage (V): AC Variable Frequency Conversion Velocity, Gear/Pin Rack Driving

Operation Mode: 3300

Dust Suppression Mode: Internal and External Spray

Design Production Capacity (t/h): 2000;2000;2500

Maximum Non-detachable Dimension (mm): 3180x2117x1100;2915x1315x905;2915x1315x905

Maximum Non-detachable Weight (kg) : 7962;8987;8987

Total Weight (t): 55;56;56

Match Feeding Machine Model: SGZ764, SGZ800, SGZ900, SGZ1000

High installed powerlow surface height, heavy body, and large coal passing space.

The shell adoptshigh-strength alloy cast steel quenching and tempering treatment and external refining, with independent intellectual property rights

The gear materialis made of high-grade alloy steel, subjected to cryogenic treatment, adopted shaping modification, and strengthened shot peening treatment to improve the service life of the gear.

The walking boxadopts a double-row wheel structure with strong load-bearing capacity. The guide is made of special grade steel material that of independent intellectual property rights, which has extremely high wear resistance.

Equipped withadvanced posture control and working face alignment systems, as well as functions of environmental perception, collision prevention, precise maintenance, and equipment lifecycle management.

Equipped withintelligent coal cutting function in the entire process section, including intelligently planned cutting and automatic triangular coal cutting.

Serialized designmultiple types of interchanges, a wide range of mining heights, and can be matched with scraper conveyors with different groove widths.

The system hasmultiple remote communication methods